Introduction

In today’s fast-paced market, the need for versatile packaging solutions has never been more critical. Businesses across various sectors are continually searching for ways to enhance efficiency, reduce waste, and ensure product safety during transit. Enter plastic packaging trays—an essential component of modern logistics that meet these demands while providing a reliable means of protecting goods.

The Need for Versatile Packaging Solutions

As consumer preferences shift and e-commerce continues to flourish, companies must adapt their packaging strategies to keep up with the dynamic landscape. Versatile packaging solutions not only safeguard products but also facilitate smoother shipping processes, making them indispensable in today’s competitive environment. Plastic trays offer a practical answer to these challenges by combining durability with flexibility, ensuring that businesses can package their goods in a way that meets both aesthetic and functional requirements.

Why Plastic Packaging Trays Are Essential

Plastic packaging trays have emerged as a cornerstone of effective product presentation and protection. Their lightweight yet sturdy design allows for efficient stacking and storage, which is crucial for optimizing space during shipping and handling. Furthermore, these trays are resistant to moisture and contamination, making them particularly suitable for food packaging trays where hygiene is paramount.

Exploring Thermoformed Trays for Food Packaging

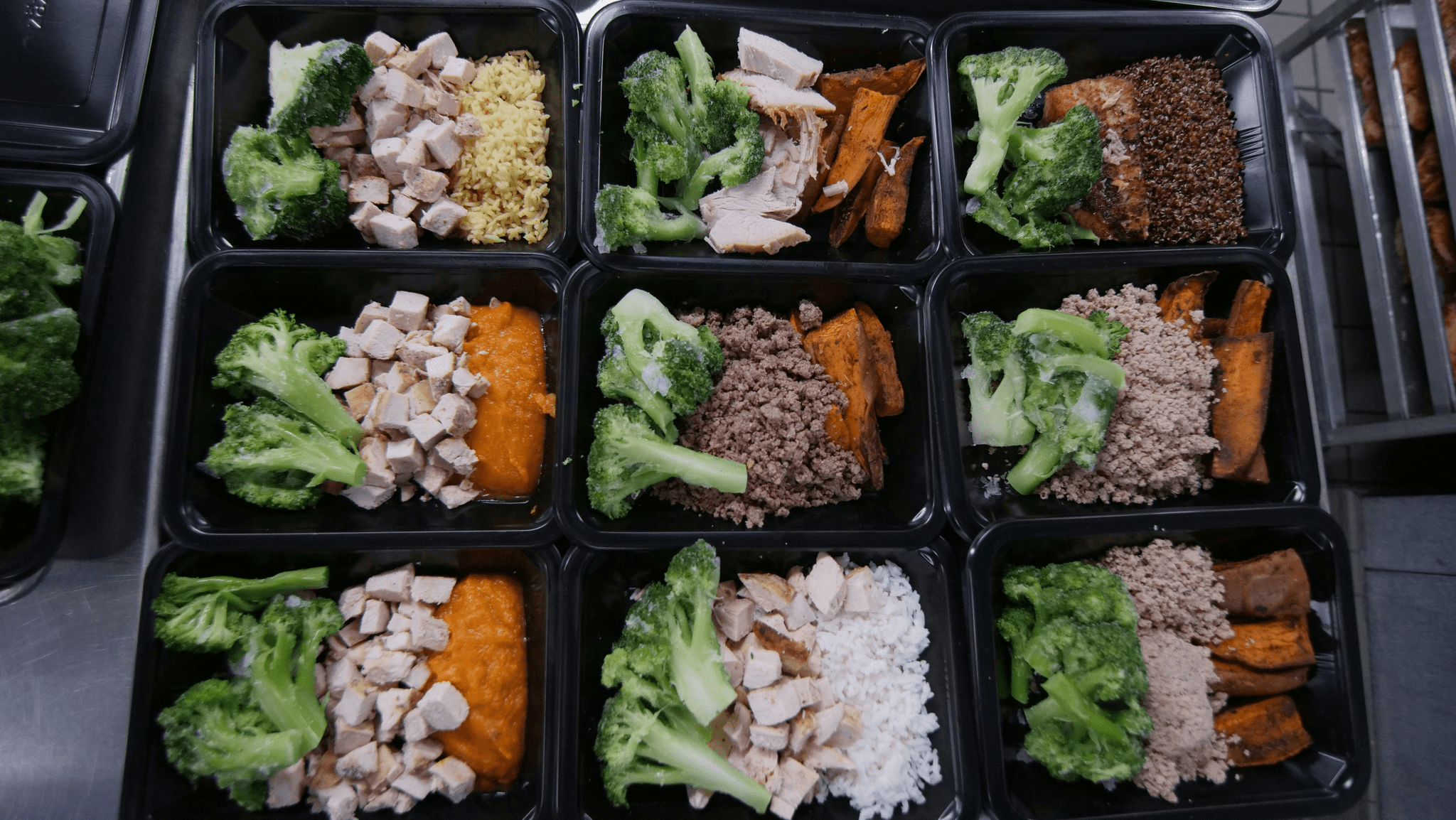

When it comes to food packaging trays, thermoformed options stand out due to their ability to be customized in shape and size while maintaining excellent structural integrity. Thermoformed plastic tray manufacturers have revolutionized the industry by creating tailored solutions that cater specifically to the unique needs of food products—from fresh produce to ready-to-eat meals. By exploring these innovative designs, businesses can enhance their brand image while ensuring that their products arrive safely at their destination.

The Rise of Plastic Packaging Trays

Plastic packaging trays have surged in popularity, transforming how products are stored and shipped across various industries. Their lightweight nature, durability, and cost-effectiveness make them a go-to choice for manufacturers looking to streamline operations while maintaining product integrity. As businesses increasingly prioritize efficiency and presentation, plastic trays continue to lead the charge in modern packaging solutions.

Benefits of Using Plastic Trays

The benefits of using plastic trays are numerous and compelling. First off, they offer exceptional protection for products during transit, ensuring that items arrive at their destination intact and undamaged. Additionally, plastic packaging trays are highly customizable; manufacturers can design custom plastic trays that fit specific product dimensions perfectly, enhancing both functionality and aesthetics.

Moreover, these trays are easy to clean and reuse, making them a sustainable option compared to traditional materials like cardboard or glass. With their resistance to moisture and chemicals, food packaging trays made from high-quality plastics maintain hygiene standards essential in the food industry. This combination of practicality and adaptability solidifies the role of plastic trays as indispensable tools for businesses everywhere.

The Role of Thermoformed Trays in Shipping

Thermoformed trays for food packaging play a pivotal role in the shipping process by providing secure containment for various products. These trays are crafted through a process that molds heated sheets of plastic into specific shapes, creating tailored solutions that meet diverse shipping needs. Their snug fit ensures minimal movement during transportation, significantly reducing the risk of damage.

In addition to protecting goods during shipping, thermoformed plastic tray manufacturers have developed designs that maximize space efficiency within shipping containers or boxes. This means businesses can save on freight costs by optimizing load capacity without compromising safety or quality. Consequently, as e-commerce continues to expand rapidly, the demand for reliable thermoformed trays is expected only to grow.

Eco-Friendly Options for Sustainable Packaging

As sustainability becomes an increasing priority across industries, eco-friendly options for sustainable packaging are gaining traction among consumers and companies alike. Many manufacturers now offer biodegradable or recyclable materials when producing plastic packaging trays—ensuring that even as we enjoy modern conveniences like custom plastic trays, we do not compromise our planet's health in the process.

These innovations include using post-consumer recycled plastics or developing new materials designed to break down more easily after disposal without leaving harmful residues behind. Such initiatives not only appeal to environmentally conscious consumers but also help companies meet regulatory requirements regarding sustainability practices. By choosing eco-friendly options in food packaging trays production, businesses can demonstrate their commitment to responsible manufacturing while enhancing their brand image.

Custom Plastic Trays for Various Industries

In today's fast-paced market, custom plastic trays are becoming essential across various industries. These tailored solutions cater to specific needs, ensuring that products are packaged efficiently and attractively. From food packaging trays to retail displays, the versatility of plastic packaging trays is unmatched.

Tailored Solutions for Food and Beverage

Thermoformed trays for food packaging allow manufacturers to create designs that fit their unique offerings while ensuring freshness and safety. With options like compartmentalized trays or those designed for specific food items, businesses can enhance their brand image while meeting regulatory standards.

Moreover, these tailored solutions often come with features like tamper-evidence or moisture barriers that protect delicate products during transportation. By investing in high-quality plastic trays from reputable thermoformed plastic tray manufacturers, companies can ensure that their products not only look good but also stay fresh longer. This attention to detail ultimately leads to improved customer satisfaction and loyalty.

Applications in Retail and E-commerce

The rise of e-commerce has transformed how businesses approach packaging, making custom plastic trays even more vital in retail settings. These versatile packaging solutions help streamline logistics by optimizing space during shipping while providing excellent protection against damage. Whether it’s a sleek tray for gourmet chocolates or an eye-catching design for a new beverage launch, the right plastic packaging trays can make all the difference.

Additionally, as online shopping continues to grow, retailers need efficient packaging solutions that are easy to handle and present well upon delivery. Custom plastic trays not only enhance the unboxing experience but also help brands stand out in a crowded marketplace by showcasing products beautifully. The combination of functionality and aesthetics is key when choosing thermoformed trays for food packaging and other retail applications.

Enhancing Presentation with Custom Designs

One of the most exciting aspects of using custom plastic trays is the ability to enhance product presentation through innovative designs. Businesses can utilize vibrant colors, unique shapes, or even embossed logos on their food packaging trays to create a lasting impression on consumers. This level of customization allows brands to convey their identity effectively while ensuring their products are easily recognizable.

Moreover, aesthetic appeal isn't just about looks; it also plays a significant role in consumer behavior at point-of-sale locations or during online shopping experiences. When customers see beautifully presented items nestled within expertly crafted plastic packaging trays, they are more likely to make a purchase decision influenced by perceived quality and care put into the product's presentation. Thus, investing in custom designs not only elevates brand image but can also drive sales growth significantly.

Choosing the Right Thermoformed Plastic Tray Manufacturers

Key Factors to Consider

First and foremost, consider the manufacturer’s experience in producing thermoformed trays for food packaging. The right manufacturer should have a proven track record of delivering high-quality plastic trays that comply with food safety regulations. Additionally, look for companies that offer custom plastic trays tailored to your product specifications—this flexibility can greatly enhance your packaging strategy.

Another important factor is the range of materials used in production. Opt for manufacturers who provide eco-friendly options, as sustainability is becoming increasingly crucial in today’s market. Finally, assess their customer support and responsiveness; a reliable partner will ensure you’re never left in the dark during your ordering process.

Leading Companies in the Industry

In the realm of thermoformed plastic tray manufacturers, several companies stand out for their innovation and commitment to quality. One notable name is Unitedpakstore, renowned for its diverse range of food packaging trays designed to meet various industry needs. Their focus on custom solutions allows businesses to showcase their products effectively while maintaining durability during shipping.

Another leader is Placon Corporation, which specializes in sustainable packaging solutions without compromising on functionality or aesthetics. They offer an impressive selection of custom plastic trays that cater specifically to food service and retail sectors. Lastly, Genpak has made a name for itself by combining cutting-edge technology with eco-friendly materials—making them a popular choice among environmentally-conscious brands.

Quality Assurance and Compliance

Quality assurance is non-negotiable when choosing thermoformed plastic tray manufacturers; after all, you want assurance that your food packaging trays are safe and reliable. Look for manufacturers who adhere to industry standards such as FDA regulations and ISO certifications; this not only guarantees product safety but also enhances brand credibility.

Moreover, inquire about their testing procedures—reputable companies will conduct rigorous quality checks throughout production stages to ensure consistency and reliability in their plastic trays. Compliance with environmental regulations is another critical aspect; choosing manufacturers committed to sustainable practices can help you achieve your own environmental goals while providing top-notch products.

Innovations in Food Packaging Trays

The world of food packaging is evolving rapidly, driven by technological advancements and a growing demand for sustainability. Innovations in plastic packaging trays are at the forefront of this transformation, paving the way for smarter, more eco-friendly solutions. As consumers become increasingly aware of their environmental impact, the need for innovative designs in Thermoformed trays for food packaging has never been more critical.

Smart Technology Integration

Smart technology is revolutionizing how we think about plastic trays in food packaging. Imagine Thermoformed plastic trays equipped with sensors that monitor freshness or temperature—this isn't science fiction; it's happening now! These smart features not only enhance food safety but also provide valuable data to retailers and consumers alike, ensuring that every bite is as fresh as possible.

Moreover, integrating smart technology into custom plastic trays can streamline supply chains by offering real-time tracking and inventory management solutions. This means that businesses can optimize their operations while providing a better experience to customers who demand transparency about their food products. With the rise of smart technology in food packaging trays, manufacturers are finding new ways to innovate and meet consumer expectations.

Biodegradable and Recyclable Materials

Sustainability is no longer just a buzzword; it's an essential aspect of modern packaging solutions. The introduction of biodegradable and recyclable materials into plastic packaging trays is changing the game significantly. These eco-friendly options help reduce waste while maintaining the durability and functionality required for effective food storage.

Thermoformed trays for food packaging made from plant-based or recycled materials are gaining traction among environmentally conscious consumers who want to make responsible choices without sacrificing quality. This shift towards sustainable materials not only appeals to consumers but also positions companies as leaders in corporate responsibility—a win-win situation! As more businesses adopt these practices, we can expect a significant reduction in single-use plastics cluttering our landfills.

The Future of Packaging Design

Innovative designs will focus on maximizing space efficiency while ensuring that products remain safe during transit and display. Custom plastic trays will play an essential role here, allowing brands to create unique presentations that stand out on retail shelves.

As we look ahead, we can anticipate exciting developments like modular tray designs that adapt based on product sizes or shapes—a game-changer for e-commerce businesses! Additionally, advancements in printing technology will enable brands to incorporate stunning graphics directly onto their thermoformed plastic trays, enhancing brand visibility without compromising sustainability goals. The future holds endless possibilities for those willing to embrace change within the realm of food packaging trays.

Unitedpakstore: Your Partner in Packaging Solutions

When it comes to packaging, Unitedpakstore stands out as a leader in providing innovative solutions that prioritize both quality and sustainability. Our plastic packaging trays are designed not only to meet the diverse needs of various industries but also to align with eco-friendly practices. With a commitment to producing top-notch thermoformed trays for food packaging, we ensure that our products are safe, reliable, and environmentally responsible.

Commitment to Quality and Sustainability

At Unitedpakstore, we believe that quality should never be compromised for sustainability. Our plastic trays are manufactured using high-grade materials that meet stringent safety standards while also being recyclable or biodegradable where possible. By investing in advanced technology and sustainable practices, we strive to minimize our environmental footprint while delivering exceptional food packaging trays that our clients can trust.

Advantages of Using Unitedpakstore Products

Choosing Unitedpakstore means opting for versatility, reliability, and customization. Our custom plastic trays can be tailored to fit any product or branding requirement, ensuring your items stand out on the shelf or during shipping. Additionally, our thermoformed plastic tray manufacturers utilize cutting-edge techniques that enhance durability and functionality—making our products ideal for everything from delicate fruits to robust retail items.

Customer Success Stories

Our clients have experienced remarkable transformations by integrating Unitedpakstore’s solutions into their operations. For instance, a local bakery improved its product presentation with our custom plastic trays while reducing waste through our eco-friendly options. Another customer in the e-commerce sector reported increased shipping efficiency and customer satisfaction after switching to our durable food packaging trays—showing how effective packaging can elevate brand perception and drive sales.

Conclusion

As we wrap up our exploration of plastic packaging trays, it's clear that these versatile solutions play a pivotal role in various industries. From food packaging trays to retail applications, the adaptability of thermoformed trays for food packaging is unmatched. With their ability to cater to diverse needs, custom plastic trays are becoming essential for businesses aiming to enhance efficiency and presentation.

Understanding the Versatility of Plastic Trays

Plastic trays have transformed the way products are packaged and shipped, offering flexibility that few other materials can match. Whether you’re looking at food packaging trays or retail displays, their lightweight yet sturdy nature ensures that items remain secure during transit. The versatility of plastic packaging trays extends beyond just functionality; they also allow for creative designs that can elevate brand visibility.

Custom Solutions for Your Shipping Needs

When it comes to shipping products safely and effectively, custom plastic trays are a game changer. They can be tailored to fit specific product dimensions and shapes, ensuring maximum protection while minimizing wasted space in shipping containers. By choosing thermoformed plastic tray manufacturers who specialize in custom solutions, businesses can optimize their logistics while providing an appealing presentation for customers.

Why Choose Unitedpakstore for Your Packaging Solutions

Unitedpakstore stands out among thermoformed tray manufacturers due to its commitment to quality and sustainability in every product offered. By investing in eco-friendly materials and innovative designs, they ensure that your plastic packaging trays not only meet your needs but also align with environmental standards. With numerous customer success stories showcasing their expertise in food packaging trays, Unitedpakstore is the go-to partner for all your packaging needs.