Introduction

In the world of food retail, meat tray packaging plays a crucial role in not only preserving the freshness of the product but also enhancing its appeal to consumers. With various types of meat packaging available, understanding which option best suits specific needs is essential for both producers and retailers. Moreover, knowing the packaging requirements for meat ensures compliance with safety standards and helps maintain high hygiene levels throughout the supply chain.

The Importance of Custom Meat Tray Packaging

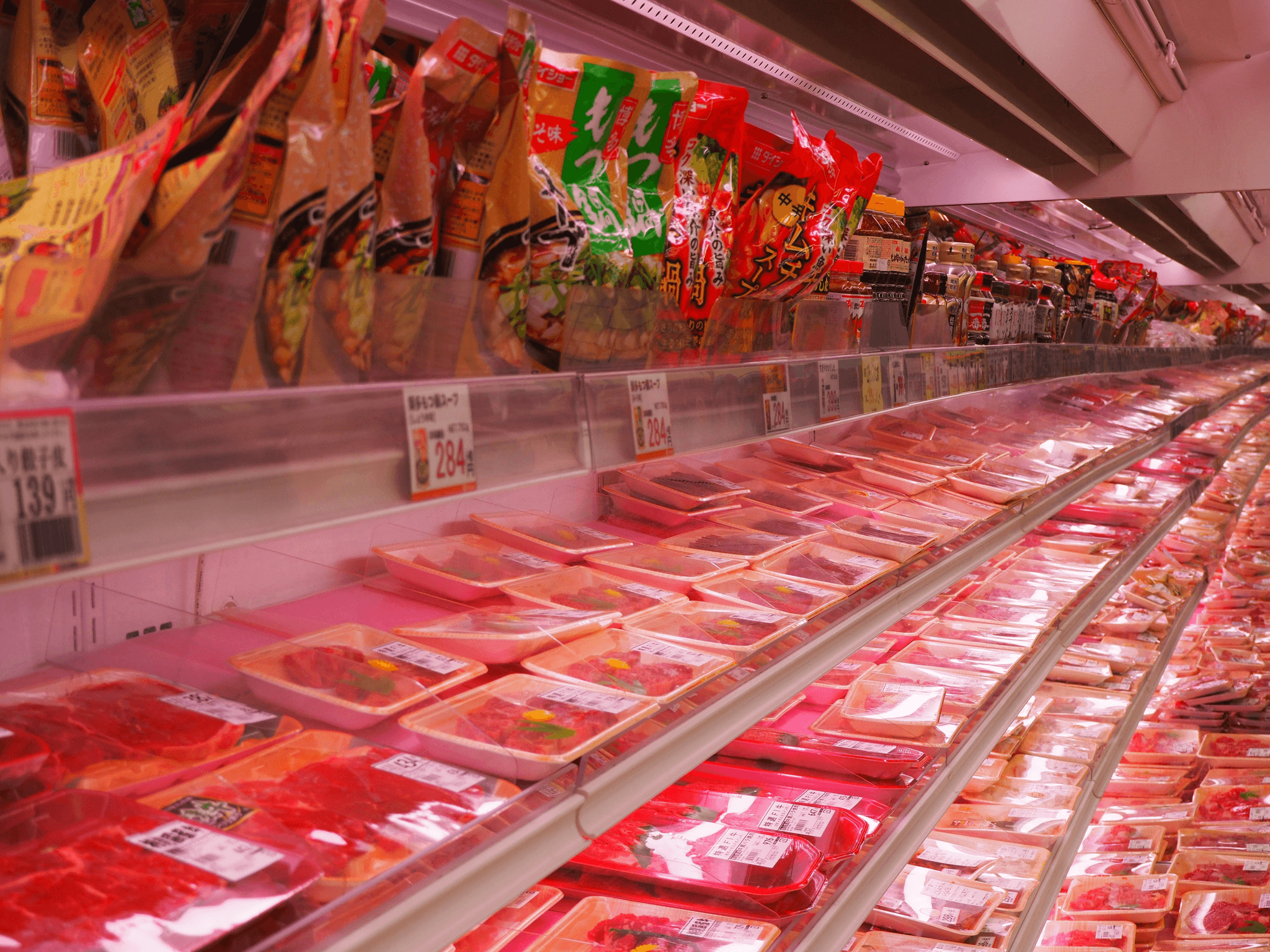

Custom meat tray packaging is vital for showcasing products attractively while ensuring they remain safe and fresh. Tailored designs can help brands stand out on crowded supermarket shelves, making it easier to capture consumer attention. Additionally, custom solutions can accommodate different foam meat tray sizes and shapes, catering to diverse cuts and varieties of meat.

Exploring the Different Types of Meat Packaging

Each type has its own set of benefits; for instance, plastic food trays are known for their durability and convenience while providing a clear view of the product inside. Innovations in meat packaging materials continue to emerge, offering enhanced protection against spoilage and contamination.

Understanding Packaging Requirements for Meat

What are the packaging requirements for meat? These include essential safety standards that ensure products remain uncontaminated during storage and transport. Additionally, proper labeling and hygiene practices must be followed to comply with industry regulations, ultimately safeguarding consumer health while maintaining product quality.

Types of Meat Tray Packaging

Exploring Foam Meat Tray Sizes

Foam meat trays are a staple in the meat packaging industry and come in various sizes to accommodate different cuts and types of meat. From small portions suitable for single servings to larger trays designed for family packs, foam meat tray sizes play a crucial role in appealing to consumers’ needs. The right size not only enhances presentation but also ensures that the product remains fresh while meeting essential packaging requirements for meat.

With foam trays being lightweight yet durable, they are often chosen for their ability to protect delicate meats during transport. Additionally, these trays often feature absorbent pads that help manage moisture – an essential factor when considering what type of packaging is used for meat. When selecting foam meat tray sizes, it’s important to consider both functionality and visual appeal to attract customers.

The Benefits of Plastic Food Trays

Plastic food trays have gained popularity as an alternative to traditional materials due to their versatility and durability in the realm of meat tray packaging. One significant advantage is their ability to be molded into various shapes and sizes tailored specifically for different types of meats, making them ideal for custom options that meet diverse consumer demands. Furthermore, plastic food trays offer excellent protection against contamination while maintaining hygiene standards—an essential aspect when considering what are the packaging requirements for meat.

Another benefit is that many plastic food trays are recyclable or made from recycled materials, aligning with growing consumer preferences towards sustainability. This eco-friendly approach not only appeals to environmentally conscious shoppers but also helps brands stand out in a crowded market where branding plays a critical role in consumer choice—after all, what is meat packaging called if not an opportunity for creative expression? With innovations continuously emerging within this space, plastic food trays remain at the forefront of modern meat packaging solutions.

Innovations in Meat Packaging Materials

The landscape of meat packaging materials has evolved significantly over recent years thanks to technological advancements aimed at enhancing freshness and shelf life while reducing environmental impact. Innovations such as vacuum-sealed bags and modified atmosphere packaging (MAP) techniques have transformed how we think about what type of packaging is used for meat—allowing products to stay fresher longer without compromising quality or taste.

Additionally, smart technologies are making waves within the industry; sensors embedded within packages can monitor temperature changes or detect spoilage indicators—an exciting development that aligns with stringent safety standards required by regulatory bodies worldwide regarding what are the packaging requirements for meat. These innovations not only improve product longevity but also bolster consumer confidence by providing transparency about freshness through advanced labeling techniques.

As we explore these cutting-edge solutions further down this outline on custom solutions from leading plastic food tray manufacturers like Unitedpakstore, it becomes clear that innovation will continue shaping how we approach effective and sustainable practices within our beloved world of meats.

What is Meat Packaging Called?

When we talk about meat packaging, it encompasses a variety of terms and concepts that are essential for both consumers and manufacturers. Meat packaging is not just about wrapping; it involves a whole ecosystem of materials, designs, and regulations that ensure safety and freshness. Understanding what meat packaging is called helps clarify the various components involved in delivering quality meat products to the market.

Defining the Terms in Meat Packaging

In the world of meat tray packaging, terminology plays a crucial role in defining processes and materials used. Common terms include vacuum sealing, which refers to removing air from the package to extend shelf life, and modified atmosphere packaging, which alters the gas composition inside the package to maintain freshness. Additionally, understanding what is meant by tray in packaging can help consumers appreciate how different foam meat tray sizes contribute to product presentation and protection.

The Role of Branding in Meat Packaging

Branding in meat packaging is not just about aesthetics; it also serves as an important communication tool between producers and consumers. Well-designed plastic food trays often feature vibrant branding elements that catch the eye while conveying essential information about quality, sourcing, and preparation methods. In a crowded marketplace, effective branding can make all the difference when asking: What type of packaging is used for meat? Strong branding reinforces consumer confidence in choosing specific products over others.

Industry Standards and Regulations

The world of meat packaging is heavily regulated to ensure food safety standards are met across all levels of production. Regulations dictate everything from material choices—such as approved meat packaging materials—to labeling requirements that inform consumers about handling instructions or expiration dates. Compliance with these industry standards ensures that all questions regarding what are the packaging requirements for meat are answered with assurance, safeguarding public health while maintaining product integrity.

What Are the Packaging Requirements for Meat?

When it comes to meat tray packaging, understanding the packaging requirements is crucial for maintaining product integrity and ensuring consumer safety. Meat packaging isn't just about putting a piece of meat in a tray; it involves adhering to strict guidelines that safeguard both the product and the people who consume it. So, what are the packaging requirements for meat? Let’s dive into them.

Essential Safety Standards

Essential safety standards are paramount in determining how meat is packaged and handled throughout its journey from farm to table. These standards ensure that meat tray packaging meets specific criteria designed to prevent contamination and spoilage. For instance, materials used must be food-safe, non-toxic, and capable of withstanding various temperatures without compromising quality.

Moreover, these safety standards dictate how long meat can be stored before consumption and under what conditions. Proper labeling is also part of these essential standards; consumers need clear information regarding expiration dates, storage instructions, and handling recommendations. Ultimately, adherence to these safety standards not only protects consumers but also builds trust in brands that prioritize quality in their meat packaging materials.

Importance of Hygiene in Meat Packaging

Hygiene plays an indispensable role in the realm of meat tray packaging. The potential for bacterial growth on raw meats necessitates stringent hygiene practices at every stage—from production to retail display. This means using clean facilities, sanitized equipment, and ensuring that all personnel involved follow rigorous hygiene protocols.

Packaging itself must also contribute to maintaining hygiene; this includes using materials that minimize exposure to contaminants while providing a barrier against external elements. Plastic food trays are often favored because they can be easily cleaned or disposed of after use without risking cross-contamination between different types of meats or other products. Therefore, prioritizing hygiene not only protects public health but also enhances the overall appeal of packaged meats.

Compliance with Food Safety Guidelines

Compliance with food safety guidelines is non-negotiable when discussing what type of packaging is used for meat products. Regulatory bodies set forth comprehensive guidelines that dictate everything from temperature control during transport to appropriate labeling practices on packages like foam meat trays or plastic food trays. This compliance ensures that consumers receive products that are safe for consumption and meet industry expectations.

Additionally, manufacturers must regularly review their processes to ensure they align with evolving food safety regulations—this includes staying updated on innovations in meat packaging materials as well as any changes in industry standards over time. Failure to comply can lead not only to legal repercussions but also significant damage to a brand's reputation if consumers feel unsafe consuming their products. Thus, compliance isn't just about following rules; it's about fostering confidence among consumers regarding their choices in the marketplace.

What Type of Packaging Is Used for Meat?

When it comes to meat packaging, several solutions are tailored to ensure freshness, safety, and compliance with industry standards. From traditional foam meat trays to innovative plastic food trays, the options are vast. Understanding what type of packaging is used for meat can significantly impact quality and customer satisfaction.

Common Packaging Solutions for Meat Products

Common meat tray packaging solutions include foam trays, vacuum-sealed bags, and modified atmosphere packaging (MAP). Foam meat trays are widely used due to their lightweight nature and cost-effectiveness; they come in various sizes to accommodate different cuts of meat. Plastic food trays are also popular as they offer durability and versatility while providing a clear view of the product inside.

Another common option is vacuum sealing, which removes air from the packaging to extend shelf life by reducing oxidation. MAP takes this a step further by altering the atmosphere inside the package to slow spoilage, making it ideal for high-quality meats. Each of these methods plays a crucial role in maintaining the integrity of meat products while ensuring compliance with what are the packaging requirements for meat.

Custom Options for Different Meat Varieties

Custom options in meat tray packaging cater specifically to various types of meats such as beef, poultry, and seafood. For instance, different foam meat tray sizes can be designed based on portion sizes or cuts like steaks versus ground beef. Customization not only enhances presentation but also helps meet specific regulatory requirements that differ among types of meats.

Additionally, some manufacturers specialize in creating bespoke plastic food trays that incorporate branding elements or unique designs tailored to individual retailers or producers. This personalization can create a strong visual appeal that attracts consumers while ensuring that each type of meat is packaged appropriately according to its characteristics and handling needs. Ultimately, custom options enhance marketability while addressing what is meat packaging called in terms of differentiation.

Choosing the Right Packaging for Freshness

Selecting the right type of packaging is essential for preserving freshness throughout the supply chain—from processing facilities to grocery stores—and eventually reaching consumers' kitchens. Factors such as permeability to gases, moisture retention capabilities, and temperature control must be considered when evaluating different meat packaging materials. The goal is always to minimize spoilage while maximizing shelf life without compromising quality.

For example, vacuum-sealed packages work wonders for extending freshness by limiting exposure to air; however, they may not be suitable for all types of meats due to varying moisture content levels. On the other hand, foam trays combined with breathable films can provide an optimal balance between visibility and protection against environmental factors affecting freshness—especially important when considering what are the packaging requirements for meat products today. Making informed choices about these aspects ensures that consumers receive high-quality products every time they shop.

Leading Plastic Food Tray Manufacturers

In the world of meat tray packaging, choosing the right manufacturer can make all the difference. With a variety of options available, businesses must consider factors like quality, customization, and compliance with industry standards when selecting their suppliers. This section will delve into notable manufacturers and innovations shaping the future of meat packaging.

Unitedpakstore and Custom Solutions

Unitedpakstore has carved a niche in providing tailored solutions for meat tray packaging that meet diverse customer needs. Their expertise in foam meat tray sizes allows them to offer products that fit various cuts and types of meat, ensuring optimal presentation and protection. By focusing on custom solutions, they enable retailers to enhance branding while adhering to what is required for meat packaging.

Comparing Industry Leaders in Meat Packaging

When comparing industry leaders in plastic food tray manufacturers, several key players stand out for their commitment to quality and innovation. Companies like Dart Container Corporation and Genpak lead the pack by offering a range of meat packaging materials designed for durability and freshness. Each brand brings unique strengths to the table; some prioritize eco-friendly options while others focus on advanced technology that enhances product visibility.

The Future of Meat Tray Packaging

The future of meat tray packaging is likely to be shaped by advancements in materials science and sustainability practices. As consumers increasingly demand eco-conscious options, manufacturers are exploring biodegradable alternatives alongside traditional plastics. Additionally, innovations such as smart packaging—integrating sensors to monitor freshness—could redefine what we understand as “what type of packaging is used for meat?” Ultimately, these trends suggest an exciting evolution ahead in how we package our favorite proteins.

Conclusion

In the ever-evolving world of food retail, custom meat tray packaging stands out as a crucial element for both producers and consumers. It not only enhances the presentation of various meat products but also plays a vital role in maintaining freshness and safety. As we have explored throughout this guide, understanding what type of packaging is used for meat is essential to meet industry standards and customer expectations.

Advantages of Custom Meat Tray Packaging

Custom meat tray packaging offers numerous advantages that benefit both sellers and buyers alike. For starters, it allows for better product visibility while ensuring that the meat remains secure and fresh—a win-win situation! Additionally, using tailored designs can help differentiate products on crowded supermarket shelves, making it easier for consumers to choose their preferred options.

Furthermore, custom packaging can be engineered to meet specific requirements related to hygiene and safety—what are the packaging requirements for meat? These trays can be designed to comply with regulations while providing an appealing aesthetic that attracts customers' attention. Ultimately, investing in custom solutions leads to improved brand loyalty and customer satisfaction.

Meeting Customer Needs with Innovative Designs

With advancements in technology and materials, manufacturers are now able to produce unique foam meat tray sizes that cater specifically to different types of meats or portion sizes. This flexibility not only enhances convenience but also aligns with consumer preferences for value-added products.

Moreover, incorporating eco-friendly materials into plastic food trays is becoming increasingly popular among companies looking to appeal to environmentally conscious shoppers. By prioritizing sustainability alongside functionality, brands can establish themselves as leaders in responsible consumption—an essential factor as consumers become more aware of their impact on the planet.

The Future of Meat Packaging in the Industry

The future of meat packaging is poised for exciting developments as new trends emerge within the industry landscape. As we continue exploring what is meat packaging called? we find that innovations will likely include smart technologies such as QR codes or RFID tags embedded within packages—allowing consumers access information about sourcing and freshness at their fingertips!

Additionally, collaborations between plastic food tray manufacturers may lead to breakthroughs in biodegradable materials or reusable containers designed specifically for meats—a step forward towards reducing waste in our environment while ensuring quality preservation during transportation and storage. Embracing these changes will shape a new era where consumer engagement meets sustainability head-on!